UL924 Requirements for Emergency Lighting Inverters

UL 924 Compliance Standards

Lighting Inverter Supply only works with UL 924 standard, tested, and certified systems, providing you with the industry’s highest capacity and efficiency systems. 90-minute lighting inverter systems provide industry-wide solutions for the current UL 924 standard.

Article 700 or 701 of the National Electrical Code, NFPA 70, the Life Safety Code, NFPA 101, the Fire Code, NFPA 1, the International Building Code, IBC, and the International Fire Code, IFC.

Standard UL 924 Requirements for Emergency Lighting

UL 924 is a set of safety standards developed by Underwriters Laboratories (UL) for emergency lighting and power equipment. These standards are designed to ensure that emergency lighting systems and related devices meet specific safety and performance criteria. The UL 924 standards are particularly important for ensuring the reliable operation of emergency lighting systems in buildings during power outages or other emergencies.

Key aspects covered by UL 924 standards include:

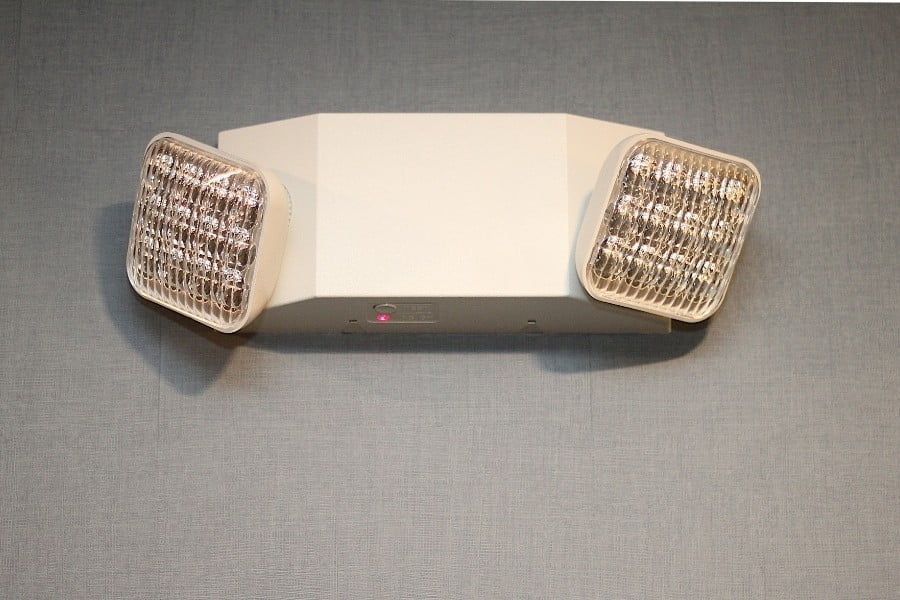

- Emergency Lighting Equipment: The standards outline requirements for emergency lighting equipment, including exit signs, emergency lighting units, and other devices designed to provide illumination during power failures.

- Battery Systems: UL 924 specifies the performance and safety requirements for batteries used in emergency lighting systems. This includes rechargeable batteries that store energy during normal operation and provide power during emergencies.

- Duration of Illumination: The standards define the minimum duration that emergency lighting equipment should provide illumination after a power outage. This ensures that occupants have sufficient time to evacuate safely.

- Testing and Maintenance: UL 924 outlines testing procedures to verify that emergency lighting systems meet the required performance criteria. Regular maintenance and testing are crucial to ensure the reliability of these systems.

- Functional Performance: The standards address the functional performance of emergency lighting, including requirements for brightness, color, and other factors that impact visibility and effectiveness.

- Installation and Wiring: UL 924 provides guidelines for the installation and wiring of emergency lighting systems to ensure they are safely and properly integrated into the building's electrical system.

- Marking and Labeling: The standards specify requirements for marking and labeling of emergency lighting equipment to provide information about its compliance with UL 924 standards.

Compliance with UL 924 standards is often a prerequisite for regulatory approval and building code compliance. Architects, engineers, and manufacturers of emergency lighting systems typically use these standards as a guide to design, test, and produce reliable and safe emergency lighting equipment.

It's important to note that standards may be updated or revised over time, so it's advisable to consult the latest version of UL 924 or other relevant standards for the most current information.

Browse Our UL 924 Approved Emergency Lighting Inverters

Solution to UL 924 Standard Requirements

Inverters help provide uninterrupted power to lighting systems in the event of an outage. This is important for facilities because emergency lighting must remain lit for at least 90 minutes when the power goes out. They also help facilities meet NFPA’s life safety requirements and UL’s 924 code, two standards your systems must meet.

90-Minute Battery Runtime Requirement

UL 924 certified lighting inverters must adhere to the NFPA Life Safety code 101 which requires the battery system provide uptime via battery runtime of 90 minutes, (1.5 hours). The requirement provides that the emergency power system restore lighting within 10 seconds after loss of normal power, and for a duration of 90 minutes from that time. This is defined by standard NFPA 101 7.9.2.2. Systems shall be of the Type 10, Level 1 System, and Class 1.5. The requirement for illumination provides for 1fc level average illumination , and 0.1 fc. minimum of Illumination level and is allowed to decline to 0.6 fc average. 0.06 fc minimum is required at the end of the 90 minute duration.

Batteries may be on board in an emergency light direct system. For central lighting inverters VRLA or lithium ion batteries produce the power at the central inverter, they are then hardwired throughout facility to the emergency lights and illumination areas. This provides several benefits.

Benefits of a Central Battery Inverter System

A Central Battery Inverter System provides for simple maintenance in one location, vs. multiple to hundreds of physical points to maintain and oversee.

- All batteries are located in the Central Inverter for access, replacement and voltage checks.

- One communications system to monitor and respond to.

- Increased options for software, notifications, remote monitoring, and data logging.

- Provides ability to use various battery options such as lithium ion, Pure Lead Batteries, and VRLA (Valve Regulated Lead Acid).

Benefits of Lithium Ion Batteries for Central Inverter Systems

UL 924 UPS systems and central Lighting Inverters also work with longer runtime lithium ion battery systems to achieve the 90 minute runtime. Lithium batteries provide much less maintenance attention and a longer physical life of the batteries. The following are benefits to a lithium ion battery for Central Inverters.

- The physical life of the battery may be extended to 12-15 years, vs. traditional VRLA battery life of 3-5 years.

- The battery does not require a physical measurement to maintain it. Therefore frequent technician maintenance visits are not required.

- The batteries provide much more detailed information about themselves in real time to flag any problems.

- The notification of issues is much more immediate and pronounced.

- Batteries are much less physical footprint, as much as 30% of a VRLA physical footprint.

- Lithium Ion batteries shed much less heat in terms of BTU, less ventilation and attention to physical room cooling hvac.

Challenges still remain with certain OEM’s to provide lithium ion systems for general products. The shorter duration load support that lithium provides requires an oversizing of the battery system. The offset of higher capital cost up front, vs. lower annual maintenance over 10 plus years is the valuation calculation customers need to perform.

VRLA vs. Lithium Ion vs. Pure Lead Batteries for Central Inverters

Customer are seeking newer technologies. The VRLA (Valve Regulated Lead Acid) Battery has been the standby in the industry for 50 plus years. The industry is just now providing the ability to combine Lithium Ion Batteries with Central Inverter Systems. Old tech meets new tech when comparing Pure Lead batteries and lithium. Below provides some detail of those options which may be readily available or upcoming for the central inverter industry.

Single Source Lighting Inverter Provider

Expert assistance from Technical Consultants assist in the selection process of your next Inverter System. Our team is available for Technical Review of specifications, Sizing assistance, Voltage selection, and Runtime Calculations.

Latest News

Stay up-to-date with Lighting Inverter's news and resources about the industry!

Request a Quote

Experienced Product Representatives are on hand to send you information and quotations for equipment. If you need help with sizing, installation planning, or general questions about product please fill in the appropriate form and someone will contact you shortly. You may also call 844-501-1887 to get a direct product representative.